Standard Tables¶

Standard tables are input tables which are mandatory of network optimization problem except “Bill of Materials”. These are 7 input tables, which are:

- Item

- Location

- Demand

- Inventory Policies

- Sourcing Policies

- Transportation Policies

- Bill of Materials

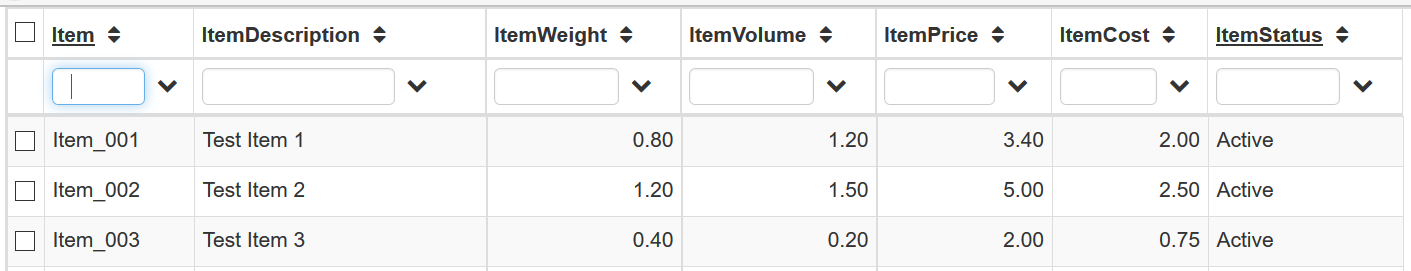

Item Table¶

Enter SKU data in this table. Underlined columns are mandatory

Column Details:

- Item: Enter a unique name/code for the item or SKU.

- Item Description: Enter description related to SKU, this field is required only for reporting purpose, it does not derive any functionality for network optimization.

- Item Weight: Enter weight of the SKU per UOM. Here UOM is the unit of measure in which user will specify demand in the model. User should make sure to have single weight UOM for all the items. Default value: 1

- Item Volume: Enter volume of the SKU per UOM. Here UOM is the unit of measure in which user will specify demand in the model. User should make sure to have single volume UOM for all the items. Default value: 1

- Item Price: Enter revenue generated by SKU per UOM. User should make sure to have single currency for all the items in the model and all the costs should also be in the same currency. System will use pricing for optimization if there is variable demand. Default Value:0

- Item Cost: Enter average cost of SKU per UOM. Average costing will be used in model to calculate inventory holding cost based on average stock values. Default Value: 0

- Item Status: User can disable/enable an item in model by changing this parameter to Active/Inactive. Default value is Active.

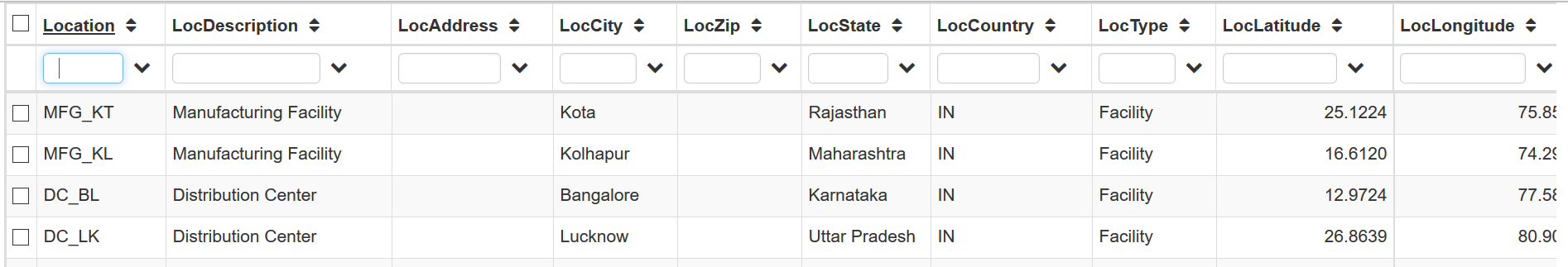

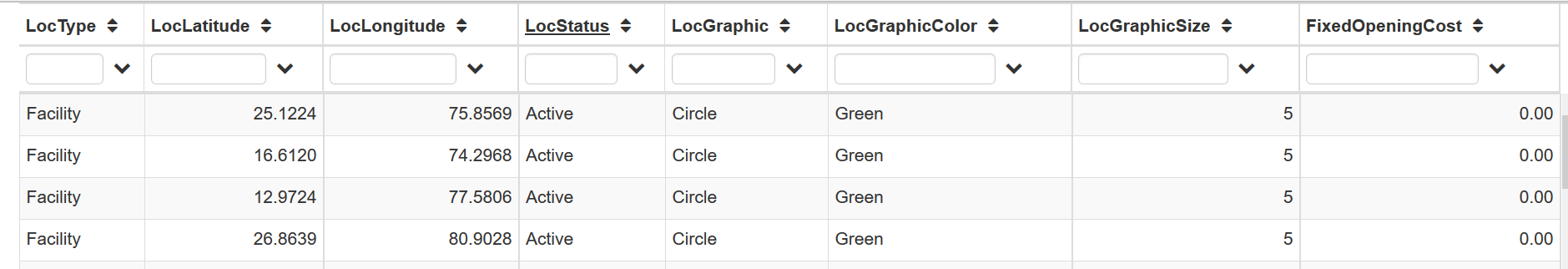

Location Table¶

Enter list of all customers, suppliers and existing facility which are in scope for network design model

Column Details:

- Location: Enter a unique name/code for each location.

- Loc Description: Enter a description for the location, required only for reporting purpose. This field does not derive any functionality.

- Loc Address/Loc City/Loc Zip/Loc State/Loc Country: Enter location address details required either for geocoding or reporting purpose.

- Loc Type: Classify location in either Facility or Customer Type. Any location which is not a customer is a Facility in the model.

- Loc Latitude/Loc Longitude: Enter coordinates for the site, site coordinates are used to calculate distance between locations and for display on a map.

- Loc Status: Enable to Disable a customer site or facility by setting this field to Active/Inactive.

- Loc Graphic/Loc Graphic Color/Loc Graphic Size: In these fields, choose how user wants to display locations on a map.

- Fixed Opening Cost: This field is required only for facilities. System will optimize based on fixed opening cost and may disable a facility if it identifies some saving in not using a facility.

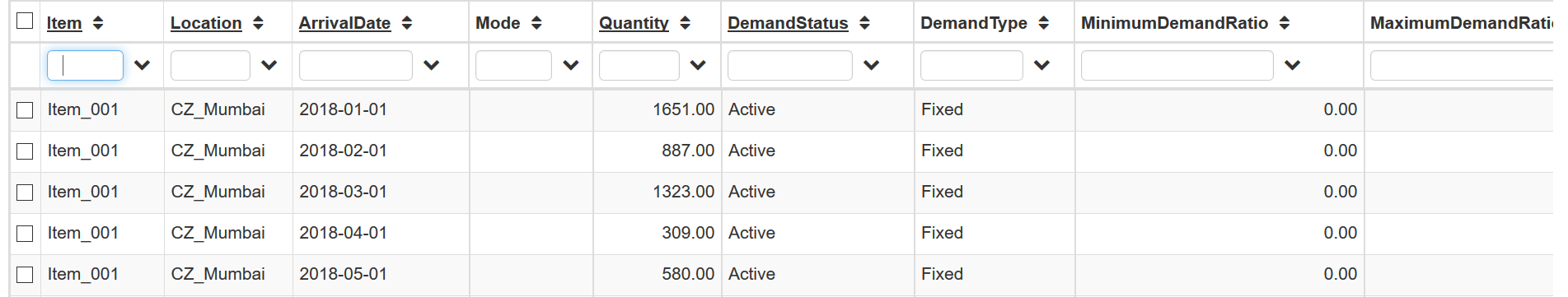

Demand Table¶

Enter sales forecast for items and customers for the horizon setup in model parameters.

Column Details:

- Item: Enter SKU name/code as defined in Item table.

- Location: Enter customer site name/code as defined in Location table.

- Arrival Date: Forecast date, if it is a multiperiod model system will use period definition and arrival date to aggregate demand by period else system will assume all the demand in a single period.

- Mode: User may specify which transportation mode to use to satisfy demand, if left blank system can choose any mode based on optimization.

- Quantity: Demand quantity.

- Demand Status: User may disable/enable demand for a particular customer, SKU, date or mode by setting this field to Inactive/Active.

- Demand Type: User may specify demand type as fixed or variable, if demand type is set to fixed system will satisfy complete demand else it will try to optimize total profit by adjusting demand between minimum and maximum. Default is set to “Fixed”.

- Minimum Demand Ratio: Only applicable if Demand Type is set to variable, system will add a constraint to set minimum demand = Quantity * Minimum Demand Ratio. Default is set to 0.

- Maximum Demand Ratio: Only applicable if Demand Type is set to variable, system will add a constraint to set maximum demand = Quantity * Maximum Demand Ratio. Default is set to 1.

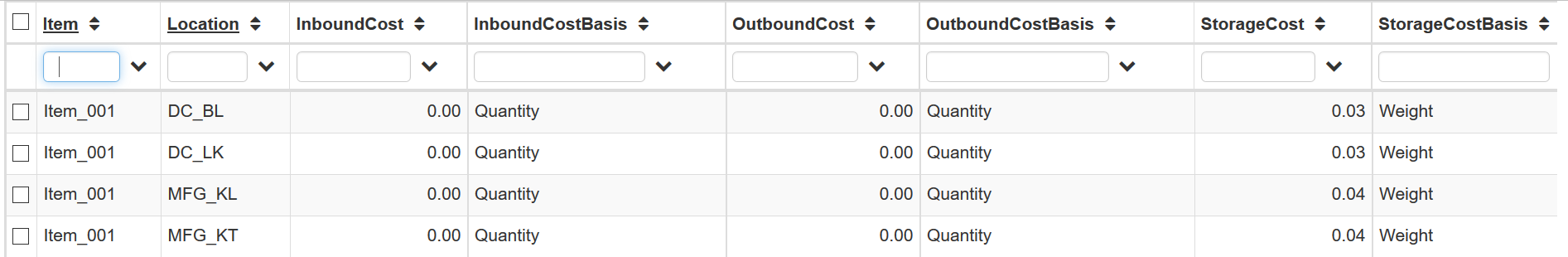

Inventory Policies Table¶

Enter data related how an item is stored at a facility and what stock norms or costs are associated with it.

Column Details:

- Inbound Cost/Inbound Cost Basis: Inbound cost is cost of handing inbound flow per Cost Basis, User may specify inbound cost per unit/weight/volume by setting up Cost Basis field. Inbound Cost default value is set to 0, Inbound Cost Basis default is set to “Quantity”.

- Outbound Cost/Outbound Cost Basis: Outbound cost is cost of handing outbound flow per Cost Basis, User may specify outbound cost per unit/weight/volume by setting up Cost Basis field. Outbound Cost default value is set to 0, Outbound Cost Basis default is set to “Quantity”.

- Storage Cost/Storage Cost Basis: Storage cost is cost of storing per Storage Basis item per period, User may specify storage cost per unit/weight/volume per period by setting up Cost Basis field. Storage Cost default value is set to 0, Storage Cost Basis default is set to “Quantity”.

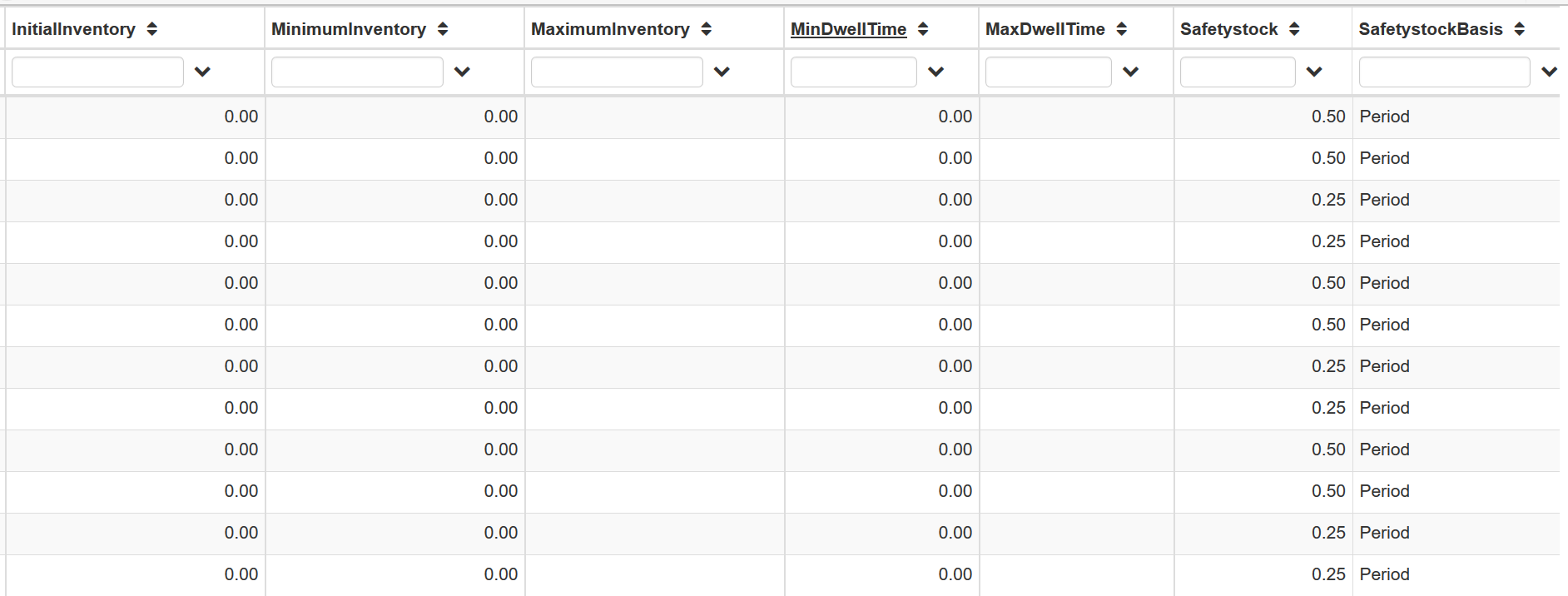

- Initial Inventory: Enter how many units of this product is on-hand at this site at the start of model horizon. Default value is 0.

- Minimum Inventory: Minimum inventory required to maintain for specific item at specified facility for each period. Default value is 0.

- Maximum Inventory: Maximum inventory that can be maintained for an item at a specified facility for each period.

- Min Dwell Time: Minimum number of periods in which an item must stay at the facility, this field is required only for multiperiod models. For e.g. if this value is set to 2 for a DC and a specific item, items which are received in Period_001 can be dispatched only in Period_003 or later periods.

- Max Dwell Time: Maximum number of periods in which an item could stay at the facility, this field is required only for multiperiod models. For e.g. if this value is set to 3 for a DC and a specific item, items received in Period_001 should be dispatched till Period_003.

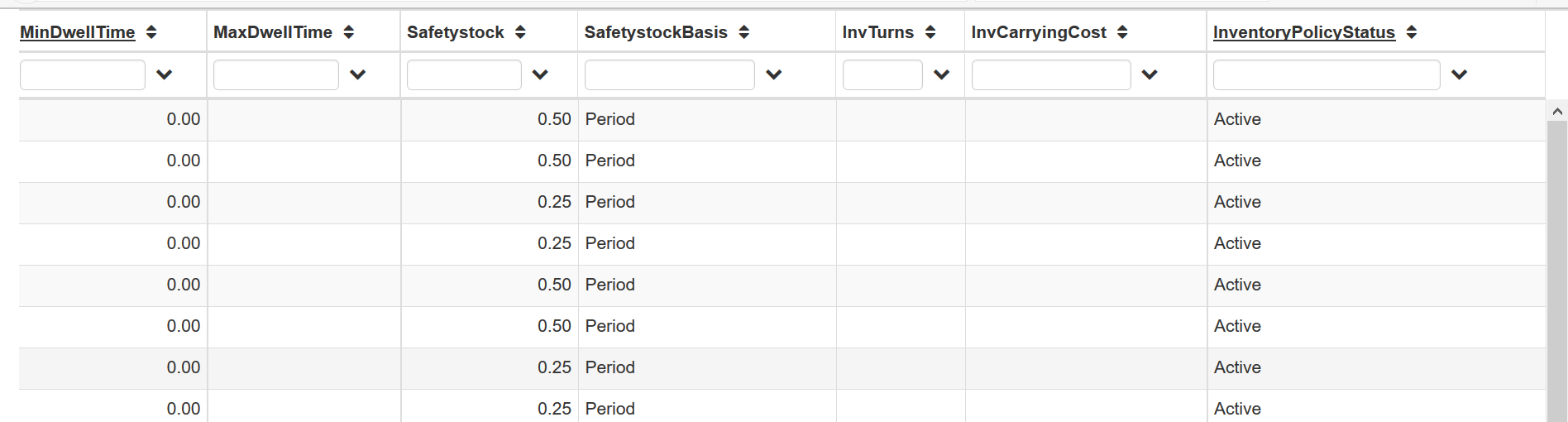

- Safety Stock /Safety Stock Basis: Safety stock required in each period based on safety stock basis, safety stock basis can be Period/Days/Quantity. For e.g. if safety stock is set to 1 and safety stock basis is set to period, system will keep safety stock equal to outbound flow for each period. If safety stock basis is set to quantity then system will keep fixed safety stock in each period.

- Inv Turns: Inventory Turns is a ratio showing average no. of replenishments done each period. Inventory Turns is used to calculate average inventory in a period. For e.g. if inventory turn is 4 and throughput is 1000 units, average inventory is ((1000/4)/2) = 125 units.

- Inv Carrying Cost (%): Enter Inventory Carrying Cost in %, this value will supersede value from model setup parameters. It is used to calculate Inventory Holding cost based on value and carrying cost %.

- Inventory Policy Status: Enable/Disable any inventory policy from the model by setting its status to Active/Inactive.

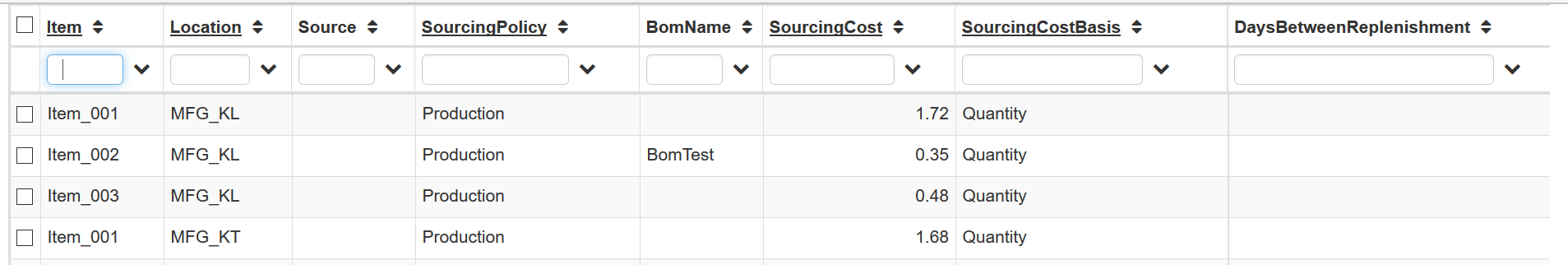

Sourcing Policies¶

Enter data related to how a product moves in supply chain.

Column Details:

- Sourcing Policy: Here, we have 3 types of sourcing policies:

- Production: It specifies which item is produced at which facility/supplier.

- Inter Facility: It specifies how an item is moved between a source facility to destination facility.

- Customer Sourcing: It specifies how an item is moved between a source facility to customer site.

- Item: Enter the Item for which sourcing policy applies.

- Location: Enter destination location if sourcing policy is of Inter Facility or Customer Sourcing type. For Production sourcing type, enter Production Facility.

- Source: Enter Source Facility in case of Inter Facility or Customer Sourcing type and leave blank for Production sourcing type.

- Bom Name: Only required for Production type sourcing. If a production requires BOM Components, user first needs to populate BOM details in Bill of Materials table and add a reference name here.

- Sourcing Cost/Sourcing Cost Basis: Add souring Cost per Cost Basis UOM to procure the item. Cost Basis can be weight/quantity/volume.

- Days Between Replenishment: Enter replenishment frequency in number of days, it is used to calculate cycle stock in the model. It is only applicable for production sourcing or inter facility sourcing.

- For e.g. DBR = Days Between Replenishment, Q = Inbound Flow (In case of interfacility sourcing) / Production Quantity (In case of production sourcing), N = No. of Days in Period, Cycle Stock = (Q/N)*(DBR/2).

- Lead Time: Enter lead time in periods, only integer values are not allowed for lead time.

- Min Sourcing/Max Sourcing/Sourcing Basis: User can specify minimum amount or maximum amount a customer or facility can procure based on values and sourcing basis.

- For Percentage sourcing basis, user needs to input value between 0 to 100. For e.g. If maximum is set to 40 for percentage sourcing basis, it means that destination site can at max procure 40% of its specific item requirement from specific facility.

- Sourcing Policy Status: User may enable/disable a sourcing policy by setting this field to Active/Inactive.

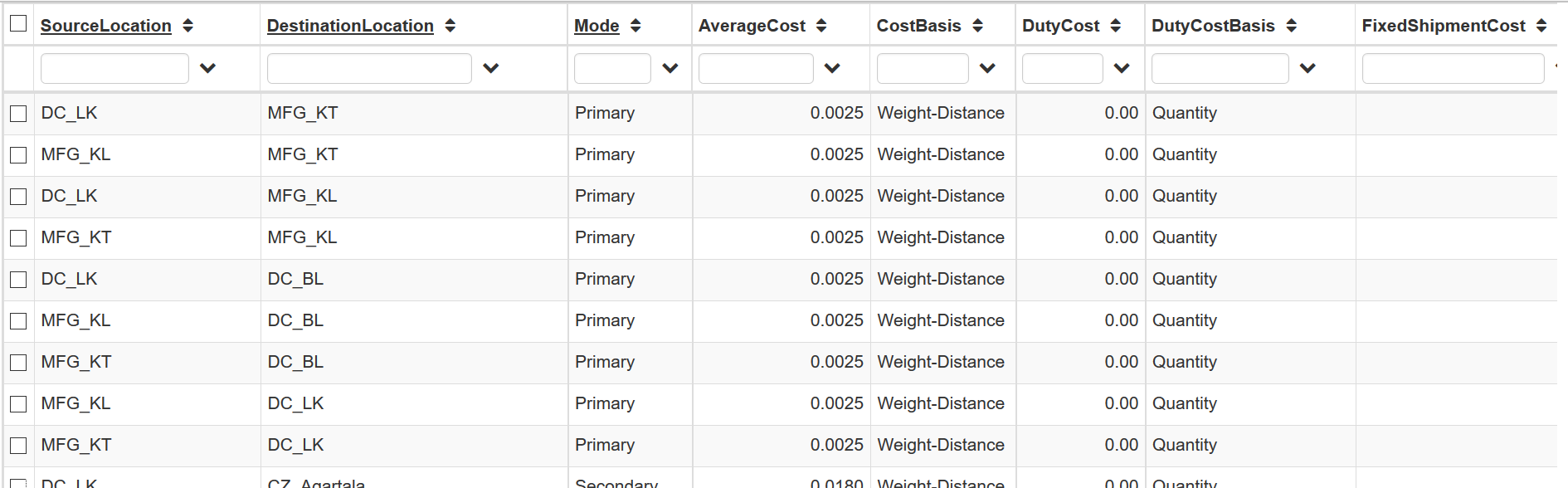

Transportation Policies¶

Enter data related to transportation lanes and cost

Column Details:

- Source Location: Enter source location from where items will be dispatched, source location will always be of facility type.

- Destination Location: Enter destination location for which items will be procured, destination location can be a facility or a customer type.

- Mode: Enter transportation mode which will carry the flow from source site to destination site. A source location pair can have multiple modes with each having different cost/capacity/constraint.

- Average Cost/Average Cost Basis: Enter Average cost of transporting goods per Cost Basis UOM, cast basis can be Weight/Volume/Quantity/Weight Distance/Volume Distance/Quantity Distance.

- For e.g. Average cost is 0.0025, Cost Basis is Quantity Distance and lane distance in 1000 KMS, then average cost will be 40 per unit.

- Duty Cost/Duty Cost Basis: Similar to average cost, user may enter duty cost by Weight/Volume/Quantity/Weight Distance/Volume Distance/Quantity Distance.

- Fixed Shipment Cost: User may add fixed shipment cost for any lane, this is cost per shipment. A shipment is calculated as int((total flow for mode-lane-period)/Shipment Size).

- Shipment Size/Shipment Size Basis: In addition to fixed shipment cost, user needs to specify max shipment size. Say shipment max size is 100 and the total flow required is 950, then the total number of shipments will be 10.

- Distance: Distance between source location and destination location in KMS/Miles.

- Transportation Policy Status: User may enable/disable a transportation policy by setting its status to Active/Inactive.